The main factors affecting the life of LED drivers

Unlike ordinary incandescent bulbs, LED lamp beads can be directly connected to AC mains. Since LEDs are characteristic sensitive semiconductor devices and have negative temperature characteristics, LED devices have almost harsh requirements for driving power. According to the characteristics of LEDs, the use of places and environmental requirements, more complex driving power must be designed for different purposes LED lamps and lighting equipment. When choosing the LED power supply, not only should various suitable parameters be selected according to the series and parallel mode of the LED lamp beads, but also a high-quality, long-life power supply should be considered to meet the needs of long-term effective operation of the LED lamp. It can be said that the life of the LED driver determines the life of the LED lamp. What factors affect the life of the LED driver?

Let's discuss the following main factors:

a. Environment

High humidity environment, high temperature environment, dusty environment, strong magnetic environment, vibration environment.

b. Power supply grid

The voltage input of the unstable power grid will have an impact on the components of the LED power supply, thereby affecting the service life of the LED driver. Therefore, when choosing a product, choose a matching input voltage and leave a certain range of fluctuations.

c. temperature

The working temperature comes from the temperature of the working environment and the temperature of the equipment, lights, etc. that wor

d. Electrolytic capacitor

The choice of electrolytic capacitor in the design directly determines the life of the driver. Also in the temperature-resistant 105℃ electrolytic capacitor, 2000Hrs and 8000hrs, the life of the two driving power supplies is obvious; for the same power supply, we choose 85℃ and 105℃ electrolysis The service life is also different. The electrolyte of an electrolytic capacitor will vaporize. This phenomenon will accelerate as the temperature increases. It is generally believed that the leakage rate will double for every 10°C increase in temperature.

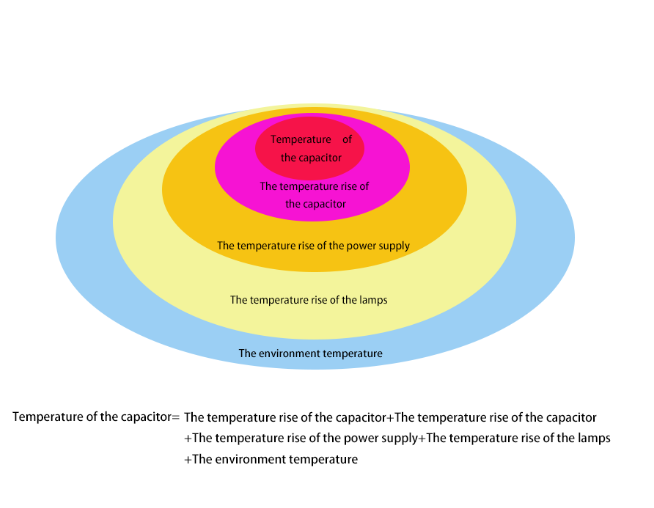

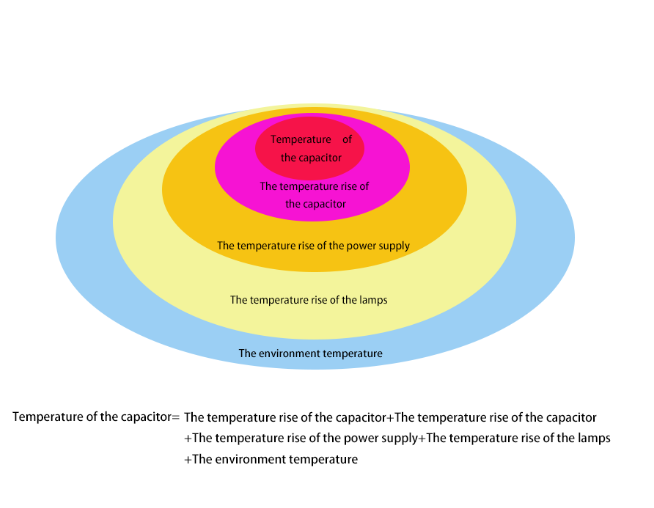

The operating environment of the power supply should be considered when selecting the power supply. The most important factor is the operating temperature of the electrolytic capacitor, which is also the most difficult to control. As shown in Figure 1, the capacitor temperature = the temperature rise of the capacitor + the temperature rise of the power supply + the lamp Temperature rise + ambient temperature rise. The temperature rise of the capacitor at high frequency depends on its circuit design and capacitor quality. The range of change is about 5 degrees. The temperature rise of the power supply depends on its heat dissipation design and efficiency. The range of change is about 30 degrees. The rise depends on the heat dissipation design and the size of the space, and the variation range is about 20 degrees. According to the Arrhenius Equation, the lifetime of the capacitor doubles every time the temperature of the capacitor drops by 10 degrees. The converse is that the temperature of the capacitor increases by 10 degrees and the lifetime of the capacitor doubles. For example, the lifetime of the capacitor at 105℃ can be guaranteed for about 8000 hours; the lifetime of the capacitor at 95℃ can be guaranteed for about 16000 hours.

Figure 1 Capacitor temperature in LED driver

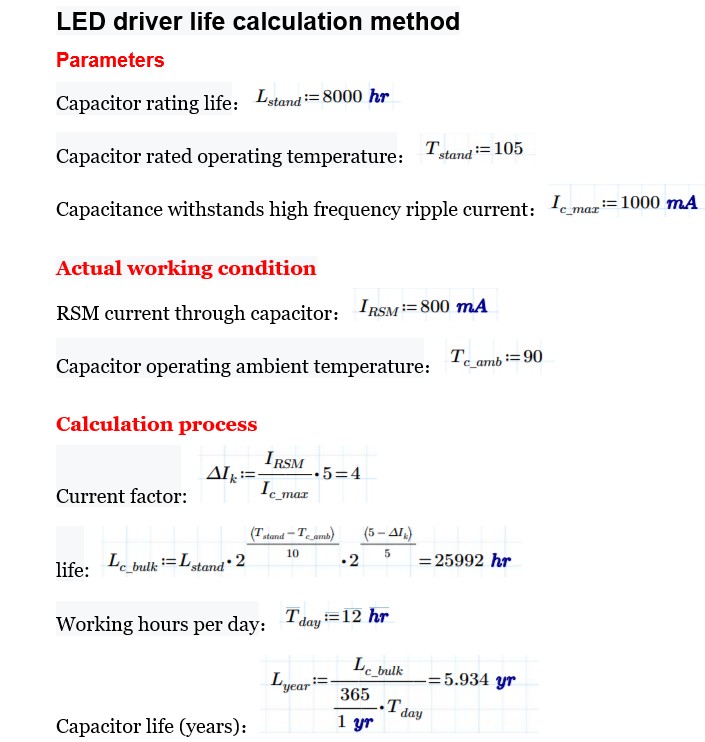

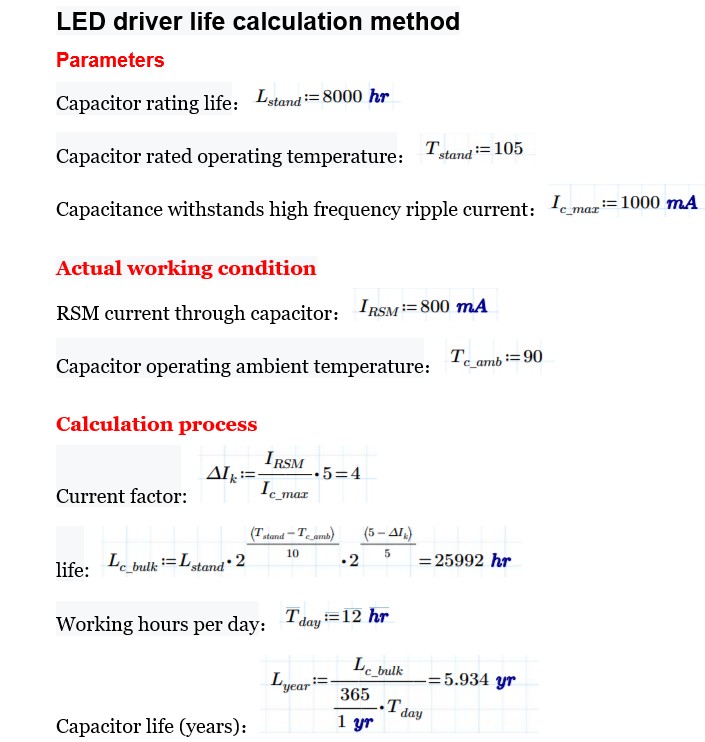

Figure 2 capacitance life calculation method

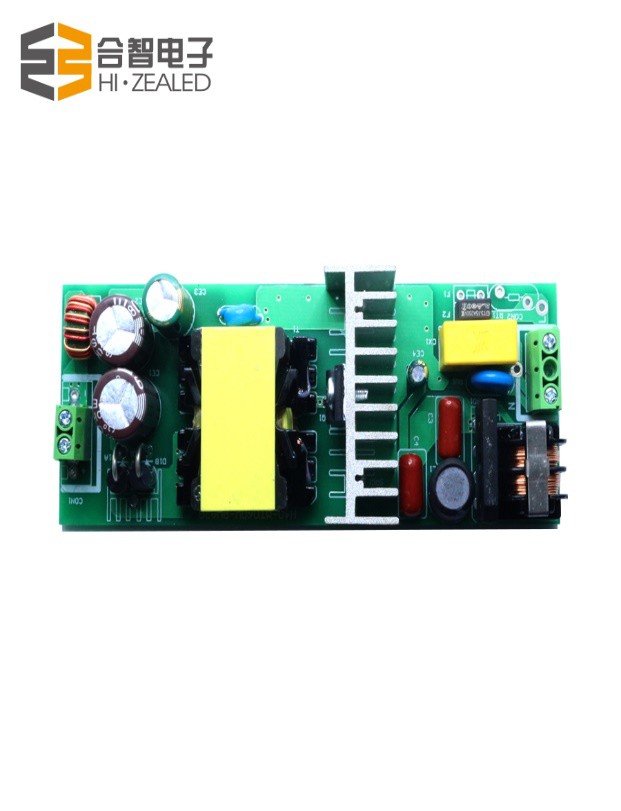

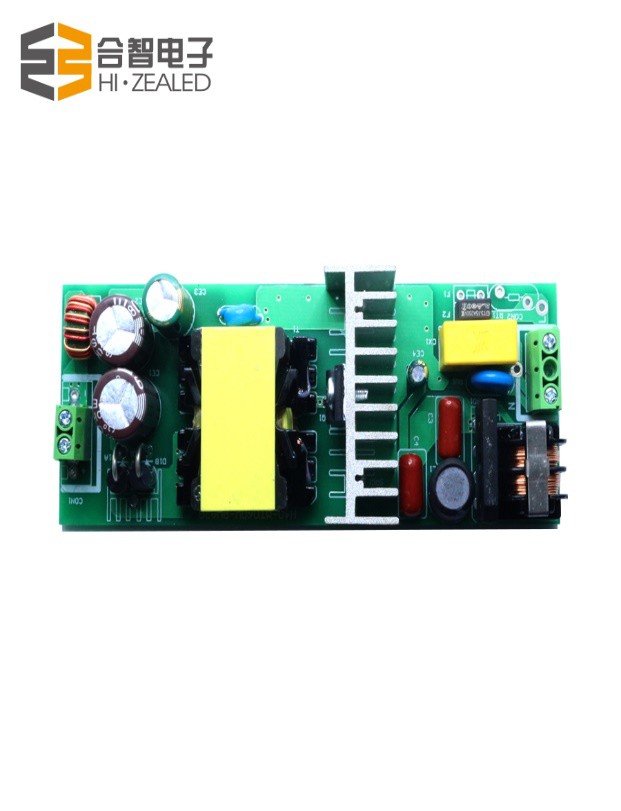

The company has been deepening in research and development, innovation and other fields, constantly optimizing products to meet customer needs. In recent years, it has increased its investment in improving the life of LED drivers. It has improved heat dissipation, the use of long-life electrolytic capacitors, and potting technology. The service life of the product has also achieved a certain effect. The warranty life of each of our products can reach at least 3 years, and the highest can reach more than 5 years, which improves the cost-effectiveness of the product. For example, our product model HZD072CXI (Figure 3), which is an LED external ceiling downlight panel light power supply, uses a 105°C electrolytic capacitor with a life span of 8000-10000hrs, and at the same time installs a heat sink for the power components to dissipate heat. This driver works in a Ta50°C environment, and can be guaranteed for more than five years at a maximum Tc temperature of 80°C.

Figure 3 HZD072CXI

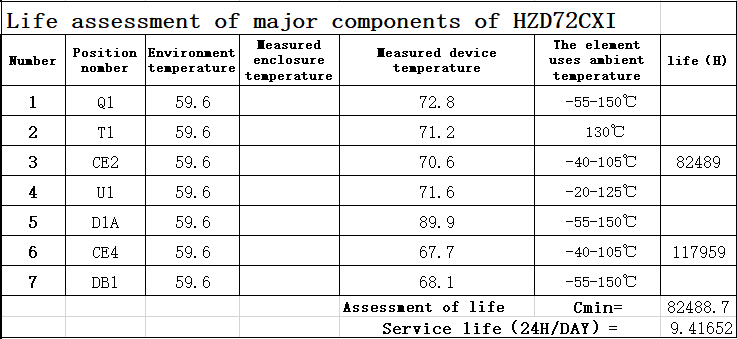

Figure 4 Life assessment of major components of HZD072CXI

Our company's products will fully consider the ifluence factors on the LED driver power supply in the early design. Through the design and the selection of power devices, the self-heating of the power supply can be minimized. The thermal factor is fully considered in the selection of electrolytic capacitors. High temperature resistance and long life specifications are often used. At the same time, we have fully tested and certified the products to ensure the efficient and long-life work of each LED Driver.